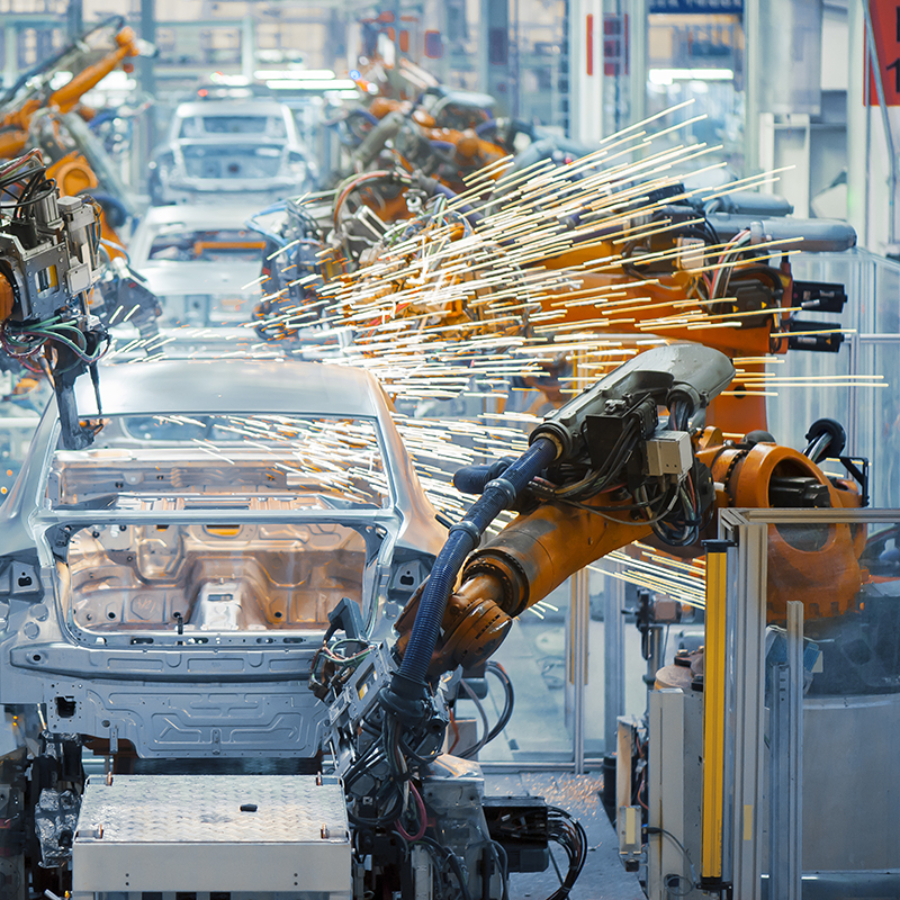

Advanced Solutions for Industrial Energy Efficiency and Power Quality

Ortea Next designs and installs complete systems for energy efficiency and industrial power quality, adapting them to the needs of each plant. Our solutions are the result of decades of experience and are distinguished by reliability, innovation and measurable results.

Diagnostics, Design and Bespoke Implementation

Every Ortea Next project starts with a detailed technical analysis of the plant and an assessment of the real electrical issues. In collaboration with the client, we develop customised solutions that solve power quality problems, minimise downtime risks and maximise energy savings.

Immediate benefits for your industry:

- Operational continuity without unwanted interruptions.

- Longer life for production equipment.

- Reduced maintenance costs and penalties for reactive energy.

- Improved energy efficiency and emission reduction.

- Fast economic return thanks to energy bill savings.

What Ortea Next Does for Industries

We are not mere device suppliers, but partners in energy innovation: we design, produce and install bespoke solutions for each industrial reality, with a complete service that includes consultancy, installation and after-sales technical assistance.

Our technologies for the industrial sector:

- Voltage stabilisers: protect production lines from voltage variations and disturbances.

- Voltage sag and micro-interruption compensators: prevent machine stops even in the presence of severe grid disturbances.

- Active harmonic filters: eliminate harmonic disturbances and protect industrial electronics.

- Low and medium voltage power factor correction systems: optimise consumption and reduce penalties for reactive energy.

- Voltage optimisers and smart devices for energy efficiency: monitor and dynamically regulate energy, ensuring maximum efficiency and sustainability.

- Isolation transformers: increase electrical safety and system stability.

All our solutions are developed in compliance with European Low Voltage and Electromagnetic Compatibility Directives, with CE certified products and Made in Italy quality.

Case Studies and Sectors Served

Ortea Next has improved the productivity and energy safety of clients in sectors such as:

- Manufacturing

- Mechanical engineering

- Food industry

- Chemical and pharmaceutical

- Foundries and paper mills

- Electroplating and electronics

- UPS systems manufacturers and continuous production lines

Request a personalised consultation: discover how to solve electrical problems in your industry and optimise energy efficiency with a tailored project.

See our case studies from around the world.

FAQ on Optimising Energy in Industries and Manufacturing

Here are answers to some common questions about energy efficiency in production:

- What are the most common electrical problems in manufacturing industries?

Voltage fluctuations, micro-interruptions, harmonics and low energy efficiency are among the main issues causing equipment damage, production stoppages and extra costs.

- How does Ortea Next solve industrial power quality issues?

Through technical diagnostics, customised design and installation of innovative devices such as stabilisers, active filters, power factor correction units and voltage optimisers.

- What tangible benefits does energy efficiency bring to industries?

Reduced management costs, greater production continuity, compliance with regulations and lower environmental emissions.