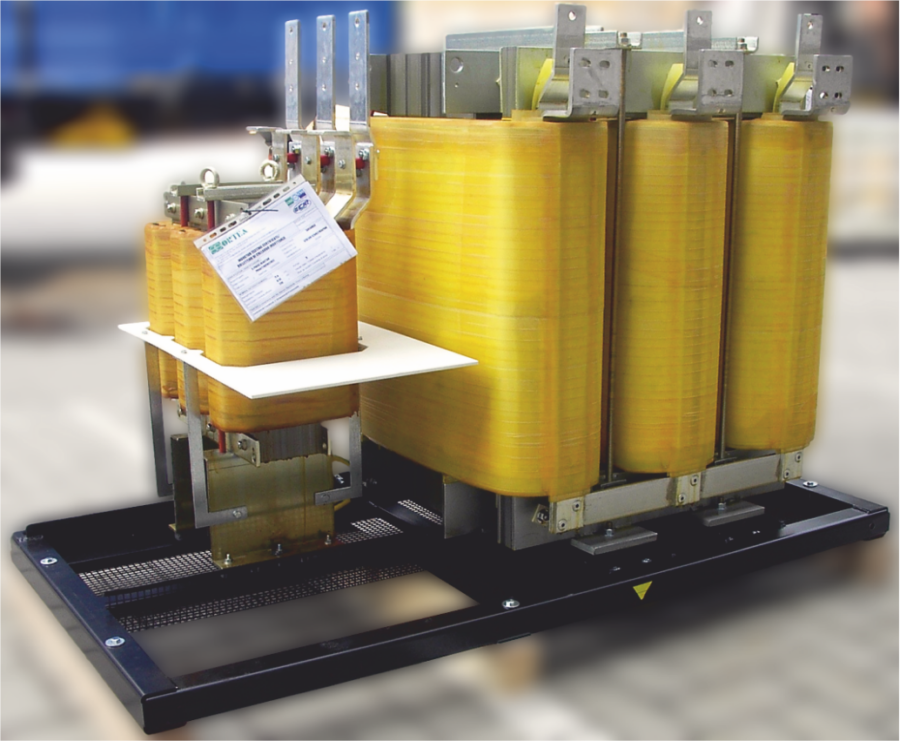

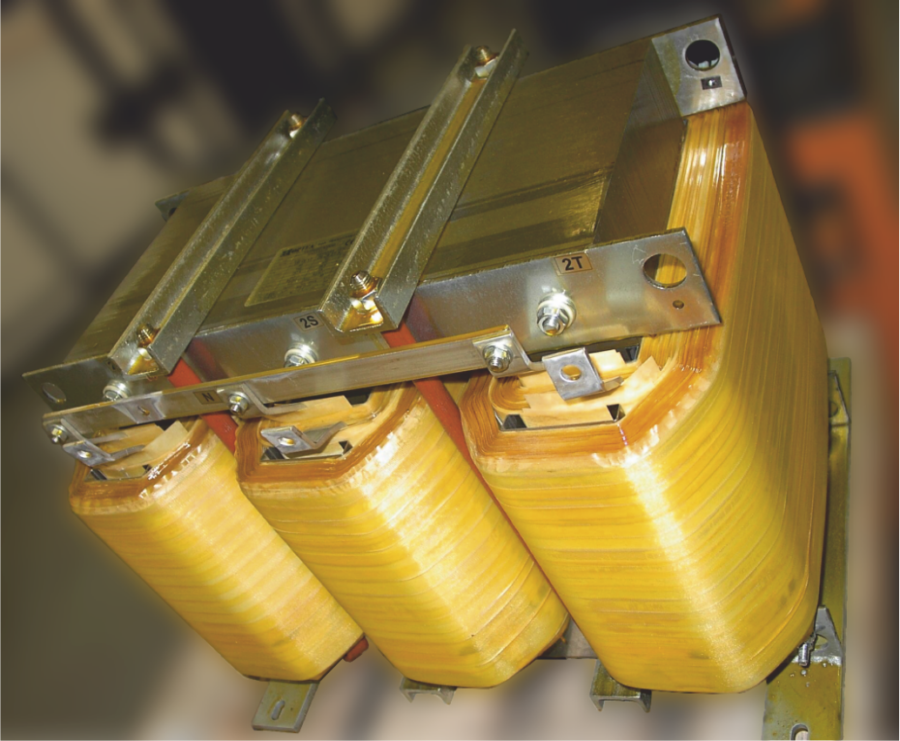

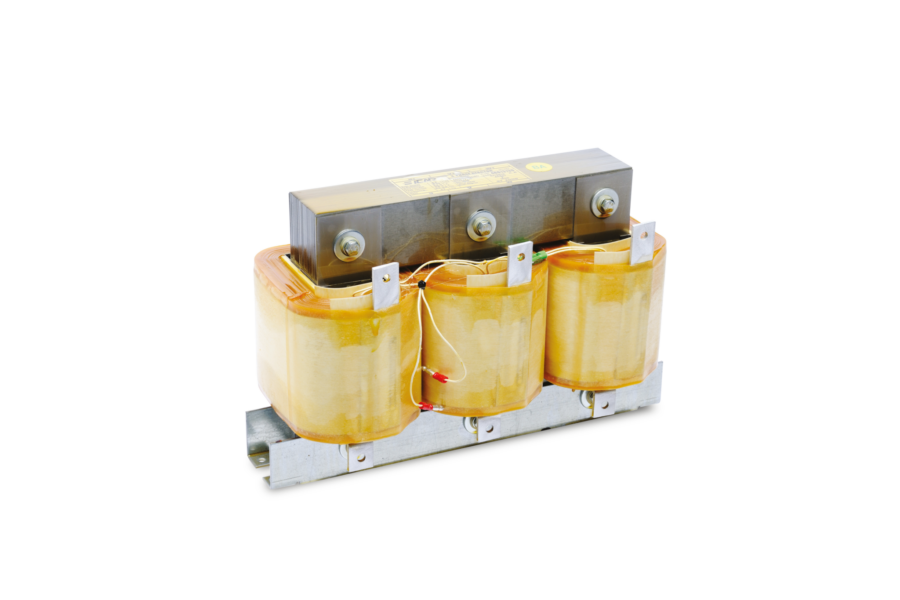

Isolation transformers are always equipped with an electrostatic screen between the primary and secondary windings.

The windings are made in a delta/star or delta/zig-zag configuration (with star center available) to eliminate the third and multiple-ofthree harmonics.

Isolation transformers perform various functions and, in particular, in data center power supply systems, they can be used for the following purposes:

- Within a UPS, to act as an integral part of power conversion circuits.

- To create a locally grounded stable neutral point.

- Inside distribution units to reduce harmonic currents.

- If equipped with sockets, to allow voltage adjustment to comply with load requirements.

- To eliminate ground loops with multiple generators or network sources.

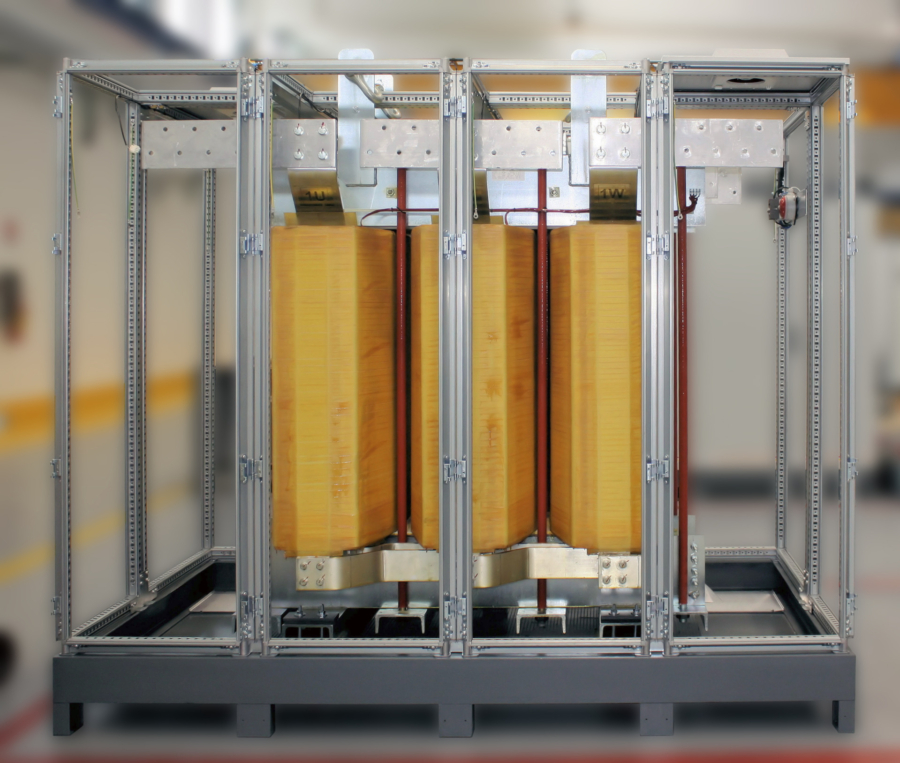

Ortea Next manufactures a range of standard isolating transformers having K factor 4, 13 and 20, but we can meet any specific need of the Customer.