THE CUSTOMER

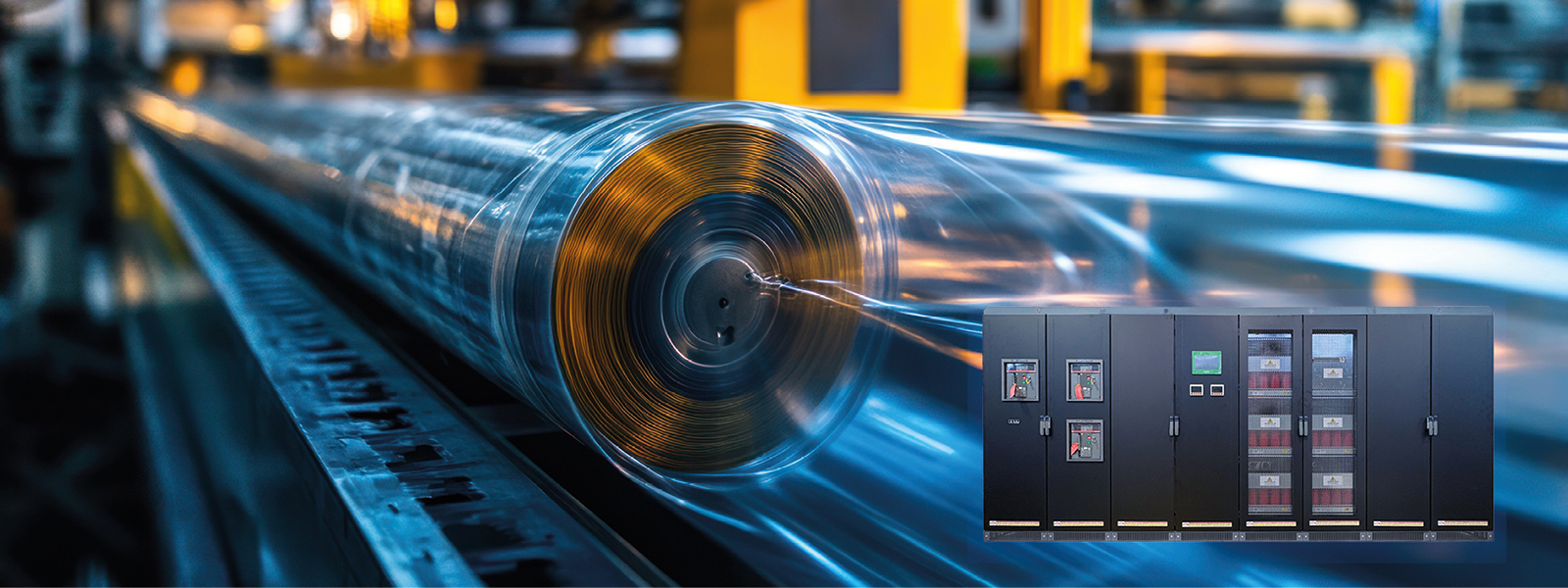

A major industrial group from Southern Italy, specialized in the production of plastic films for the agricultural and industrial sectors.

THE REQUIREMENT

Through an in-depth measurement campaign, the customer documented around 600 micro-interruption events per year, with voltage drops of up to 90% of the nominal value. Although this frequency falls within the limits of the IEC EN 50160 standard, it proved incompatible with the company’s production requirements.

The company’s energy manager quantified the overall economic impact of these disturbances, which included:

- Sudden stoppages of extrusion and winding lines

- Impairment of the quality of the material being processed during transients

- Increase in production scrap and in energy costs due to restarts

- Negative impact on productivity and on meeting delivery times

This phenomenon affected all three production plants, with losses that management estimated at over 200,000 euros per year, considering both direct and indirect costs.

OUR SOLUTION

Oxygen Zero represents the most advanced technological evolution for protection against micro-interruptions. Based on a high-efficiency electronic technology that uses supercapacitors instead of traditional batteries, the system offers significant advantages in terms of reduced maintenance, environmental sustainability and operational reliability. The device intervenes automatically in a few milliseconds, instantly detecting the voltage drop and restoring the nominal level before sensitive loads can be affected.

For the case study in question, Ortea supplied an integrated and customized solution for all four main production lines:

- Oxygen Zero 1000K (Line 1)

- Oxygen Zero 1000K with integrated 4×250 A circuit breaker (Line 2)

- Oxygen Zero 1500K (Line 3)

- Oxygen Zero 500K (Line 4)

According to the company’s estimates, this configuration represents an investment that paid for itself in less than 18 months thanks to the elimination of production stoppages caused by micro-interruptions.