When reliability, innovation and business continuity become indispensable, the plastics industry needs state-of-the-art technological solutions to protect its production processes. This is the case at a major manufacturing plant in North America, specialising in the production of plastic piping systems for plumbing, industrial, gas, irrigation, heating and chemical and petrochemical applications.

THE PROBLEM: MICRO INTERRUPTIONS AND CRITICAL PRODUCTION ISSUES

The plant was subject to an increasingly common phenomenon in industrial power networks: micro interruptions. Events of very short duration, but sufficient to cause unplanned shutdowns of sensitive machinery, compromising the efficiency of production lines and causing downtime, waste and economic losses.

THE SOLUTION: OXYGEN ZERO, TECHNOLOGY AND CUSTOMISATION

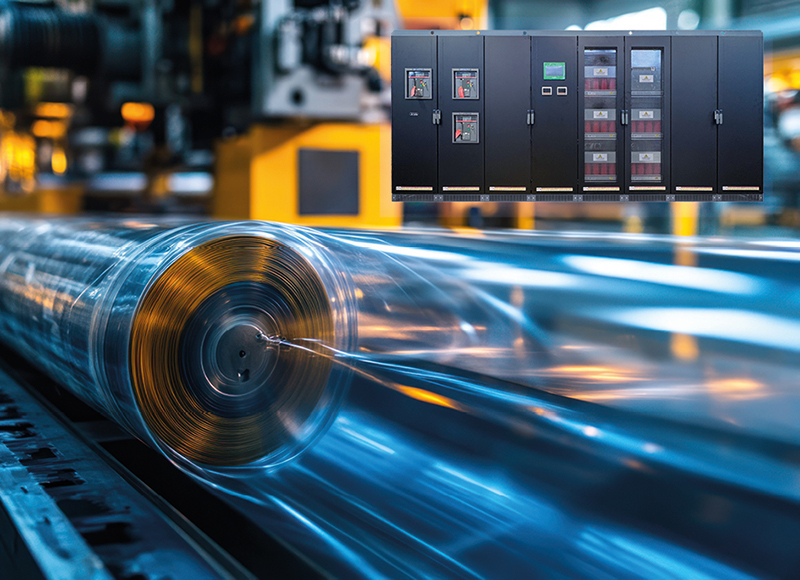

To eliminate the risk of downtime and improve power quality, Ortea supplied a 500Kva, 480V, 60Hz Oxygen Zero, designed for the North American market and custom-configured.

Compared to the standard model, the implemented solution features:

- Extended compensation of up to 3 seconds, thanks to an upgraded supercapacitor battery, providing protection even during prolonged outages.

- Input and output circuit breakers for safe and automated power management.

- Integrated bypass system, ensuring continuity even during technical interventions or maintenance.

- Dual mains analyser, for continuous and precise control of power supply quality.

OXYGEN ZERO: THE EFFECTIVE ANSWER AGAINST MICRO INTERRUPTIONS

The choice of Oxygen Zero confirms its effectiveness as the reference solution for protection against micro-interruptions in the industrial environment.

Capable of intervening in less than 2 milliseconds, Oxygen Zero provides power even in the absence of voltage, with a configurable duration of up to 3 seconds.

Thanks to its modular architecture, total absence of batteries, low maintenance and high efficiency, it is the ideal choice for all production realities that cannot afford interruptions, especially in a global context where network quality is not always guaranteed.