The sector of electric motor test benches is seeing sustained annual growth of 6.5%, reaching a global market value of 1.8 billion USD in 2024 according to MarketsandMarkets. In this context, manufacturing companies need increasingly reliable power supply solutions to guarantee precise and repeatable tests.

For a large multinational energy and industrial company, Ortea designed and built an 800 kVA multi-tap autotransformer for an engine test bench combined with a 60Hz frequency converter. The goal: to obtain precise test voltages on engines with different specifications to ensure safety, stability and maximum system reliability.

WHAT ARE THE CHALLENGES IN SUPPLYING A MOTOR TEST BENCH?

Designing power systems for motor test benches involves complex technical challenges, especially when high power levels and multiple voltage levels are required.

MAIN TECHNICAL REQUIREMENTS

Modern test benches must support different international standards. In this specific case, the main technical requirements were:

- Rated power: 800 Kva

- Input voltage: 400 V (1.155 A)

- Multi-tap outputs: 440 V, 480 V, 600 V, 690 V

- Permitted inrush current: maximum 3 times rated current (3·In)

STABILITY AND ACCURACY: WHY THEY ARE CRITICAL

According to industry studies, a production stoppage caused by malfunctions in test benches can cost from 10.000 to 200.000 EUR per day, depending on the size of the plant. For this reason, supply voltage stability and measurement repeatability are non-negotiable parameters.

HANDLING MOTORS WITH DIFFERENT SPECIFICATIONS

The multi-taps make it possible to adapt the voltage to different motor standards (NEMA, IEC) without replacing the power supply equipment, replicating real operating conditions during testing and reducing setup time and costs.

THE RISKS OF INCORRECT SIZING: INRUSH CURRENTS AND MULTIPLE TAPS

Designing a multi-tap autotransformer for motor test benches presents specific critical issues that require advanced electromagnetic expertise.

THE INRUSH CURRENT ISSUE

On 800 kVA machines, keeping inrush current to 3 times rated current is a significant engineering challenge. Transient peaks at start-up can reach values 10-15 times higher than rated current if specific design measures are not adopted.

MULTI-TAP DESIGN COMPLEXITY AT HIGH POWER

In an 800 kVA autotransformer, the reduced number of turns limits the possible combinations for obtaining four precise output levels. Achieving voltages of 440 V, 480 V, 600 V and 690 V with accuracy, thermal balance and efficiency above 98% (IEC 60076 standard) requires advanced electromagnetic calculations and extensive design experience.

ELECTRODYNAMIC STRESSES AND THERMAL MANAGEMENT

An autotransformer must handle currents higher than its rated power would suggest, requiring massive conductor bars and low-impedance paths. Managing electrodynamic stresses and heat dissipation becomes critical when “bulky” components must coexist in limited spaces.

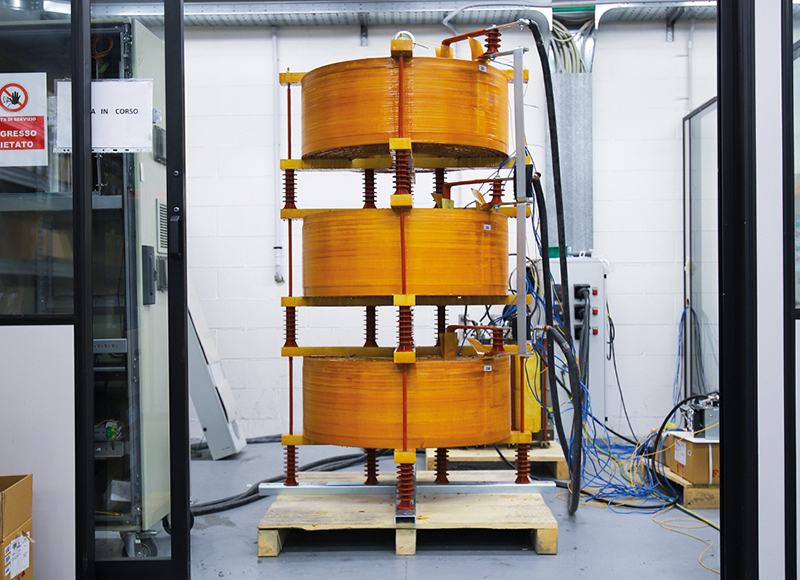

THE ORTEA SOLUTION: 800 KVA AUTOTRANSFORMER WITH CUSTOM DESIGN

Ortea developed the solution through a complete design process, in compliance with IEC 60076-11:2019 for dry-type transformers, in force since July 2019 and updated with new safety and performance requirements.

ELECTROMAGNETIC DESIGN AND 3D CALCULATION

The engineering team carried out:

- Advanced electromagnetic modelling to optimise the magnetic circuit and the geometry of the windings.

- 3D thermo-mechanical analysis to manage thermal dissipation and electrodynamic stresses.

- FEM (Finite Element Method) calculations to verify the distribution of stray fluxes and limit losses.

MECHANICAL CONSTRUCTION FOR MAXIMUM ROBUSTNESS

The construction included specific design measures:

- Optimised core geometries to reduce stray fluxes

- Windings with oversized cross-section to limit impedance

- Conductor bars with low-resistance paths to minimise losses

- Cooling systems sized for prolonged test cycles

FINAL TECHNICAL CHARACTERISTICS OF THE MACHINE

The custom project for multi-tap autotransformers produced a machine with optimal performance:

- Efficiency above 99% at full load

- Inrush current kept within 3·In

- Total losses below 2% of rated power

- Compliance with climatic classes E2 C2 F1 according to IEC 60076-11

WHY CHOOSE ORTEA NEXT’S EXPERIENCE FOR MAGNETIC PARTS?

With more than 50 years of experience in developing custom magnetic solutions, Ortea is a reliable partner for critical industrial applications.

CERTIFIED RELIABILITY FOR CRITICAL APPLICATIONS

Ortea solutions are designed in accordance with the most stringent international standards:

- IEC 60076-11 for dry-type transformers

- IEC 60076-5 for short-circuit withstand capability

- IEC 60076-10 for noise control

- ISO 9001 and ISO 14001 quality certifications

100% Custom Solutions Based On Customer Requirements

Each project is developed through a structured process that includes requirements analysis, selection of optimal materials, advanced electromagnetic sizing and 3D engineering to optimise footprint and performance.

COMPLIANCE WITH INTERNATIONAL STANDARDS

All Ortea autotransformers are designed in compliance with the IEC 60076 family of standards, the international reference updated in 2024 with new criteria for energy efficiency and environmental sustainability.

FREQUENTLY ASKED QUESTIONS (FAQ) ABOUT AUTOTRANSFORMERS FOR TEST BENCHES

- Why is an autotransformer recommended for 60Hz test benches?

Because it allows for multiple voltage levels with better space efficiency than a transformer, making it ideal when you need to vary the voltage while maintaining stability and precision. - What are the multi-sockets (440/480/600/690V) for?

To adapt the voltage to different motor standards and replicate real operating conditions during testing, without replacing the power supply equipment. - How is the inrush current limited to 3In for high power ratings?

With optimised core/winding geometries, stray flux management, careful choice of materials and current paths, as well as specific design features developed in similar applications. - Why are ‘oversized’ bars needed?

To maintain low impedance and reduced losses at high currents, ensuring thermo-mechanical stability and reliability even during transients and prolonged test cycles.