Companies producing technical plastic components by injection moulding, such as cable ties and polyamide fastening systems, operate highly automated plants, often running 24/7 to serve global markets. In these contexts, every unplanned production stoppage means loss of parts, raw material, energy and, above all, customer trust

Among the most insidious causes of line stoppages are micro interruptions on the grid: very short events (in the order of milliseconds) during which the voltage disappears and then comes back, but that brief loss is enough to shut down drives, PLCs and control systems. The result? Injection moulding presses stopped, moulds full of solidified material, scrap to be handled and long restart times

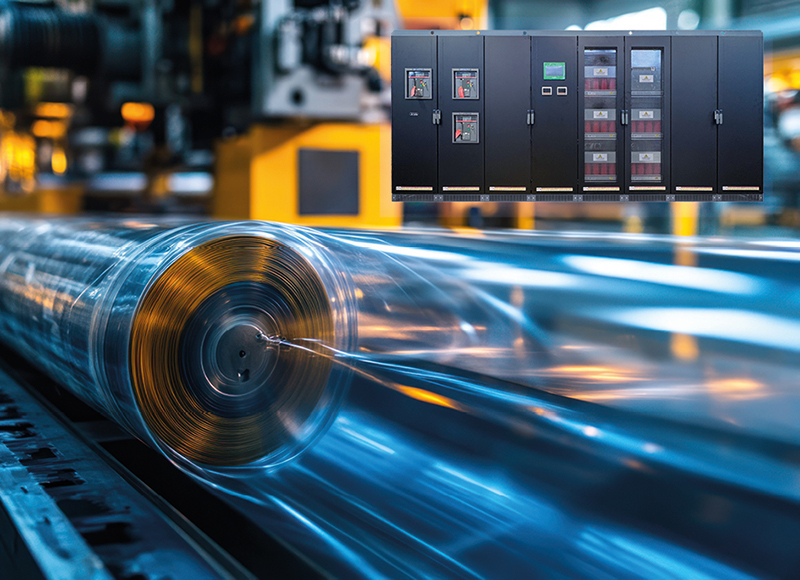

To safeguard production continuity, in this case Ortea Next supplied a 1000 kVA Oxygen Zero K micro-interruption compensator to a major Italian manufacturer of injection-moulded plastic components, a solution specifically designed for this type of disturbance.

MICRO INTERRUPTIONS IN INJECTION MOULDING: SMALL EVENTS, BIG PROBLEMS

To understand the impact of the solution, it is useful to clarify the nature of the problem.

- A voltage sag (sag) is a temporary reduction of the voltage between 90% and 10% of the nominal value, lasting from 10 ms up to 1 minute.

- A micro interruption, on the other hand, is a real loss of supply, typically a few milliseconds long, in which the residual voltage drops to zero and then returns to its nominal value.

In an injection moulding plant, these events trigger a chain of consequences:

- Sudden stoppage of presses

The drives and control systems of the presses go into fault and stop. Even if the energy returns immediately, the machine needs to be restarted and stabilised again. - Solidified material in the mould

The polymer (often PA66 polyamide, widely used for technical components and cable ties) requires very precise temperature and pressure profiles. An interruption during the cycle causes irregular solidification of the material, with the risk of incomplete parts, voids, internal stresses and cosmetic defects. - More scrap and downtime for mould cleaning

The parts in the cavities at the time of the interruption almost always have to be scrapped. In the worst cases the line must be stopped to remove solidified material from nozzles and hot runners. - Waste of raw material and energy

Each restart requires reheating, restoring parameters and bringing the process back to steady-state conditions. On lines producing millions of parts per day, this translates into significant costs and an impact on overall OEE.

- Delivery delays and risk of penalties

In just-in-time supply chains, a few hours of stoppage can jeopardise delivery schedules and lead to contractual penalties or the loss of future business.

The paradox is that “the power didn’t go out for hours”: these are very short events, difficult to detect without dedicated power quality measurements, yet sufficient to stop the entire production process.

THE ORTEA RESPONSE: A 1000 KVA OXYGEN ZERO K AGAINST MICRO INTERRUPTIONS

To protect the moulding lines, Ortea Next proposed and supplied a 1000 kVA Oxygen Zero K, a micro-interruption compensator designed to ensure continuous supply to the most sensitive loads.

Oxygen Zero K is a battery-less compensator based on IGBT technology and supercapacitors.

In practice:

- Instantaneous intervention in the event of a micro interruption

When the grid voltage collapses (down to −100%, therefore even in the event of a complete interruption), the system switches to the energy stored in the supercapacitors in less than 5 ms, keeping the output voltage within nominal limits. - Load coverage for the entire duration of the event

Oxygen Zero K is sized to supply the load for the typical duration of micro interruptions (up to 1 second at full load, extendable with derating), preventing presses, robots and conveyors from stopping. - Seamless return to the grid

When the disturbance ends, the unit resumes drawing energy from the grid and recharges the supercapacitor bank, ready for the next event.

To complete the solution, Oxygen Zero K integrates:

- Incoming and outgoing automatic circuit-breakers

- Manual bypass line with mechanically interlocked circuit-breaker, to guarantee maintenance and continuity of service even if the compensator is offline

- Class II surge protection devices on the output, to protect loads from impulse overvoltages

- 10″ multilingual touch screen and Modbus TCP/IP communication for supervision and integration into plant monitoring systems.

OXYGEN ZERO K VS TRADITIONAL UPS SYSTEMS: WHY IT IS THE RIGHT TECHNOLOGY

Micro interruptions can also be addressed with UPS systems, but for large industrial installations such as plastic moulding lines, a dedicated compensator like Oxygen Zero K offers clear advantages:

- No batteries to manage

Supercapacitors have a much longer service life than traditional batteries and do not require the same maintenance and periodic replacement activities. - Higher energy efficiency

Efficiency above 99% translates into lower losses and less heat to dissipate. There is no need for a dedicated air-conditioned room, as is often the case for large UPS banks. - Reduced footprint

For the same power rating, a compensator specifically designed for sags and micro interruptions generally takes up less space and requires a simpler infrastructure. - Solution targeted at the real problem

Oxygen Zero K is designed to handle brief sags and micro interruptions typical of industrial networks, without oversizing solutions to cover long blackouts which, in these sites, are far less frequent.

- Native integration into industrial plants

Thanks to integrated protections, communication interfaces and the ability to handle unbalanced loads rich in power electronics, Oxygen Zero K fits perfectly into complex lines composed of presses, robots, conveyors and vision systems.

THE ADVANTAGES OF CHOOSING ORTEA AS A POWER QUALITY PARTNER

Behind a single project such as the supply of a 1000 kVA Oxygen Zero K lies the experience of a company that has been designing and manufacturing solutions for power quality and energy efficiency since 1969.

Choosing Ortea Next as a power quality partner means:

- A single specialised point of contact

Voltage stabilisers, sag and micro-interruption compensators, transformers, power factor correction and active filters: a complete portfolio to tackle every low-voltage network issue. - Standard and custom solutions

Beyond the catalogue ranges, Ortea Next can develop customised configurations in terms of power, performance, layout and interfaces, starting from the specific requirements of the customer’s plant. - Made in Italy and certified quality

All solutions are designed and assembled in Italy, with a certified quality system that controls every stage, from components to final testing. - Support throughout the entire lifecycle

Power quality measurements, data analysis, commissioning, scheduled maintenance and remote monitoring services ensure long-term performance and reliability of the solution.

In short, it is not just about installing a device, but about designing an energy continuity strategy that considers the production process, the characteristics of the network and the company’s performance goals.

FAQ: MICRO INTERRUPTIONS AND PLASTIC INJECTION MOULDING

- What exactly is meant by a micro interruption on the grid?

A micro interruption is a complete loss of supply voltage, of very short duration (typically a few milliseconds). Unlike voltage sags, where the voltage is reduced but never goes to zero, during a micro interruption the residual voltage drops to 0% of the nominal value for a limited time. - Why are micro interruptions so critical for injection moulding presses?

Because modern presses are full of electronics: drives, electric motors, PLCs, supervision systems. Even a very brief “hole” causes the controls to lose power, leading to faults and cycle interruption. The material inside the mould can solidify irregularly, generating scrap and, in some cases, requiring cleaning or even disassembly of the mould. - Is a UPS not enough to protect the plant against micro interruptions?

A UPS can protect against many disturbances, but for industrial loads of hundreds or thousands of kVA it presents some drawbacks: large footprint, the need for batteries (with related cost and maintenance), lower efficiency and coverage often designed for longer blackouts, which are not the main issue here. A micro-interruption compensator such as Oxygen Zero K is specifically designed for sags and micro interruptions, is battery-less, offers very high efficiency and integrates more effectively into existing industrial plants. - How can I tell if there are micro interruptions in my moulding plant?

Typical signs are: sudden stoppages of presses with no apparent cause; frequent resets of PLCs and drives; “mains failure” or “undervoltage” alarms recorded in drive logs; scrap concentrated at specific times of day, perhaps coinciding with the start-up of large loads in the plant or on the local network. To be sure, it is advisable to carry out a power quality measurement campaign with dedicated instruments, in order to record events and correctly size the protection solution. Ortea Next supports customers in this phase too, with dedicated measurement and analysis services.